Turning today’s waste into tomorrow’s renewable energy

“Splitting CO₂” and Carbon Capture and Storage (CCS) are two very different approaches to dealing with carbon dioxide (CO₂), especially in the context of climate change and reducing greenhouse gas emissions.

Splitting Carbon Dioxide vs CCS

O=C=O

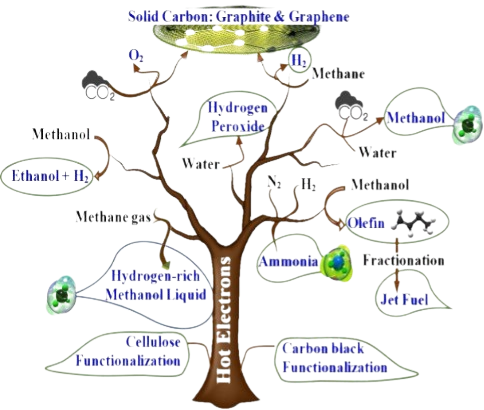

Global NRG is able to remove carbon dioxide permanently from the atmosphere using its Hot Electron technology to split carbon dioxide into solid carbon and oxygen. We do not need to store the carbon as is necessary in CCS, because we have developed technologies that turn the carbon into valuable by-products that benefit the environment and yield a profit. Once having split the CO2 molecule into its components, carbon and oxygen, it is no longer a GHG that affects Climate Change.

The problem to date with splitting CO2 has been that the amount of energy needed to break the bond between the carbon and the oxygen if using thermal energy, is so high that it makes it too expensive to be viable.

Using Hot Electrons however to do this and then converting the carbon into high yielding by-products means that not only is it viable, but the return from the by- products means it will be profitable as against the $600 or more per tonne it costs for CCS.

Global NRG is a long-established WTE group, having been in business since 1976. We always look at what by-products we can make during the process of turning the waste into energy that will make it profitable. We regard CO2 generated from fossil fuels and other sources as a waste.

Capturing and splitting CO2

Our Hot Electron reactors can also be installed directly into the flues of cement manufacturing plants, coal-and-gas-fired power plants, oil refineries, ship funnels, or almost any industry that is emitting carbon dioxide, so as to split the CO2 into carbon and oxygen thereby removing its effect on carbon pollution and climate change.

There exists a very substantial market for extracting CO2 directly from the atmosphere (DAC), on farms, in municipalities that operate a lot of fossil-fuelled vehicles, burn a lot of coal and gas-generated electricity, run sewage treatment works, and so on, which pushes up their carbon footprints. We can easily split this captured CO2 turning the carbon into carbon-related products such as nanotubes, graphite and graphene.

We are developing new ways of extracting CO2 straight from the atmosphere using amine powders that absorb and releases CO2 so that they can be recycled many times over. There is an incredibly large market for such a product, not only via what we are doing, but because in the future many industries will use our CO2 splitting technology instead of CCS that costs around $600 per tonne, because by using our technology, not only will they be able to remove the carbon dioxide, but they can do it profitably.

Carbon derived products

A huge market exists for carbon derived products using additional Global NRG technologies. These include:

Tuffcrete

Global NRG’s Tuffcrete, involves adding a small percentage of graphene powder to cement during manufacture, which will increase the concrete’s strength made from it by up to 35%. This means that less concrete needs to be used and that cement emissions will be reduced.

Tufftire

By adding graphene nano powder during tire manufacturing, it results in tires (tyres) that last as much as 40% longer. From a commercial vehicle point of view this is a significant saving..

Batteries

A combination of water and graphite could create energy storage systems which recharge in a matter of seconds and have an almost infinite lifespan,

Tufftar

Tufftar is a Global NRG process that involves adding a small amount of graphene powder to asphalt to be used for sealing roads, it reduces the incidence of potholes occurring, thereby reducing the annual cost of road maintenance by as much as 32% pa.

Water

Using graphene sheets in water treatment removes micro plastics; and using it in saltwater desalination means that the resulting cheap water can be pumped inland using WTE electricity, by running the pipelines in the corridor alongside the rail tracks and then be used for potable and agricultural purposes in dry areas to increase food production.

Graphite

Graphite has a wide variety of almost contradictory uses. An allotrope of carbon and one of the world’s softest minerals, its uses range from writing implements to lubricants and electrodes. Its use in electronics is increasing. Under high pressures and temperatures, it converts to diamond.

Very High Density (VHD) graphite plays a key role in AI and data centre cooling and can fetch as much as $200,000/tonne.

The Financial Advantage of Splitting CO2 over CCS

So, while we are successfully removing carbon dioxide from the atmosphere, manufacturing, mining, refining and power generation, by splitting the carbon dioxide molecule into carbon and oxygen, we don’t need to store it as Carbon Capture and Storage (CCS) does, by instead converting the carbon into other worthwhile products. From a cost point of view this makes the task far more acceptable to carbon polluters. Perhaps to be called Carbon Capture and

Conversion, (CCC) in the future?

Outside of the multitude of other uses, it will be a long time before the demand arising from cement, road sealing, tire (tyre) manufacturing and water purification options are exhausted as markets for our carbon-based products, while carbon dioxide will continue to be generated by industry and other sources, so there will be no lack of feedstock for our carbon technologies either.