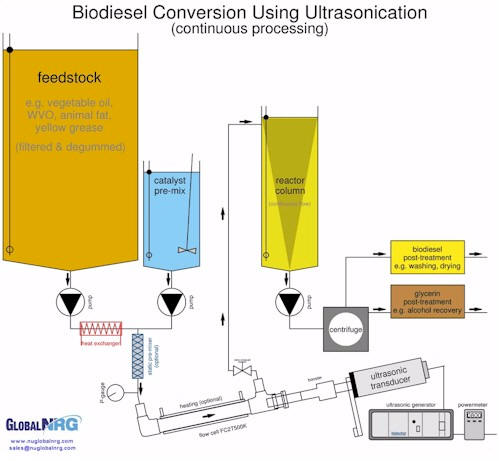

Ultrasonic Mixing for Biodiesel Production

Global NRG offers ultrasonic mixing reactors for the production of biodiesel at any scale. The ultrasonic mixing improves mass transfer and reaction kinetics leading to faster transesterification and higher yield. It saves excess methanol and catalyst.

Ultrasonic reactors are recommended for production capacities of 0.25ton (80 gal) per hour or more. Global NRG offers ultrasonic reactors of an individual capacity of up to 16 ton/hr (5100 gal/hr). In general you should consider using three to five units in parallel to accommodate variations in production rates.

Lower Material Costs and Boost Biodiesel Yield

Excess methanol and catalyst are significant cost factors in biodiesel production. Global NRG ultrasonic reactors add cavitational shear to the mixing process. This gives you much smaller methanol droplets resulting in improved methanol and catalyst utilization. Therefore, less methanol and catalyst are required. In addition to that, the cavitation influences the reaction kinetics, leading to faster and more complete transesterification.

Small and Medium Scale Biodiesel Reactors

For small and medium size biodiesel production of up to 9 ton/hr (2900 gal/hr), Global NRG offers you the GIP500hd, GIP1000hd and GIP1500hd. These three ultrasonic reactors are very compact, easy to integrate or retro-fit. They are built for heavy duty operation in harsh environments. Below you will find recommended reactor setups for a range of production rates.

| ton/hr | gal/hr | |

|---|---|---|

| 1x GIP500hd |

0.25 to 0.5

|

80 to 160

|

| 1x GIP1000hd |

0.5 to 1.0

|

160 to 320

|

| 1x GIP1500hd |

0.75 to 1.5

|

240 to 480

|

| 2x GIP1000hd |

1.0 to 2.0

|

320 to 640

|

| 2x GIP1500hd |

1.5 to 3.0

|

480 to 960

|

| 4x GIP1500hd |

3.0 to 6.0

|

960 to 1920

|

| 6x GIP1500hd |

4.5 to 9.0

|

1440 to 2880

|

Full Scale Industrial Biodiesel Reactors

For industrial processing biodiesel production plants Global NRG offers the GIP4000, GIP10000 and GIP16000. These ultrasonic processors are designed for the continuous processing of high flow rates. The GIP4000 and GIP10000 can be integrated into standard sea freight containers. Alternatively, all three processors are available in stainless steel cabinets. The upright installation requires minimal space. Below you find recommended setups for typical industrial processing rates.

| ton/hr | gal/hr | |

|---|---|---|

| 3x GIP4000 |

6.0 to 12.0

|

1,920 to 3840

|

| 5x GIP4000 |

10.0 to 20.0

|

3,200 to 6,400

|

| 3x GIP10000 |

15.0 to 30.0

|

4,800 to 9,600

|

| 3x GIP16000 |

24.0 to 48.0

|

7,680 to 15,360

|

| 5x GIP16000 |

40.0 to 80.0

|

12,800 to 25,600

|

Inline Ultrasonic Mixing of Oil and Methanol

Ultrasonic mixing reactors replace tank agitators and other dynamic shear mixers. The ultrasonic reactors are generally installed to mix two feed streams. Oil and methanol (with catalyst). For this, a crude pre-mix is pumped into the ultrasonic reactor, where the ultrasonic cavitation mixes and emulsifies both reagents within 5 to 15 seconds. This is an inline mixing process. When the mix exits the flow cell reactor, the glycerin will separate by gravity within less than 60 minutes. Alternatively, you can feed the mix into a centrifuge after several minutes of residence / reaction time. The inline mixing reduces the number and volume of tanks used for conventional batch processing. This improves capital utilization.

_p0100.jpg)